Location: Home >> Product >> Plastic Sheet Butt Welding Machine >>ZW3000 Plastic Sheet Bending Machine

Products

- Hydraulic Butt Fusion Welding Machine

- Plastic Sheet Butt Welding Machine

- Manual Butt Fusion Welding Mahcine

- Workshop Fitting Welding Machine

- Automaitic Butt Fusion Welding Machine

- Hand Extruder

- Socket Fusion/PPR Welding Machine

- Spare Parts of Welding Machine

- Data Logger

Contact Us

Huida Butt Fusion Machinery Co.,Ltd.

Tel: 0086-575-81785912

Cellphone: 0086 - 15705855718

E-mail: fusionwelder@zjbuttfusion.com

Plastic Sheet Butt Welding Machine

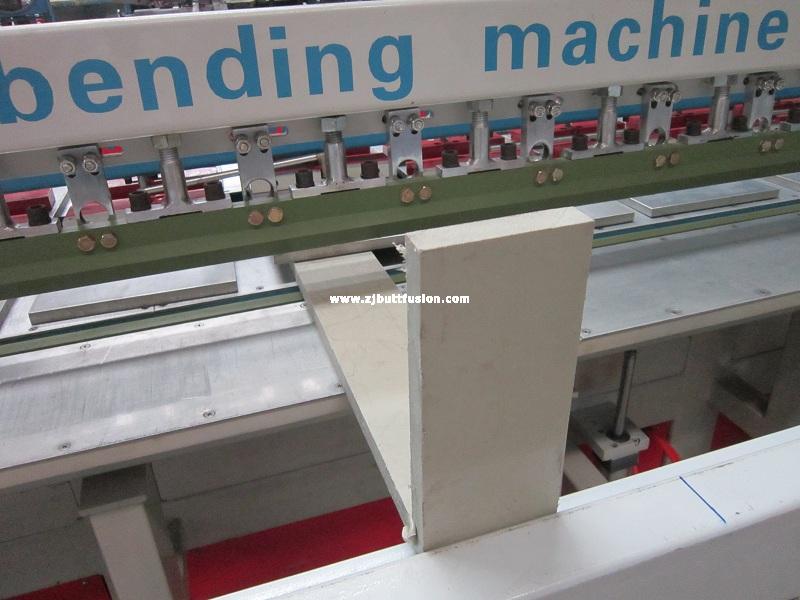

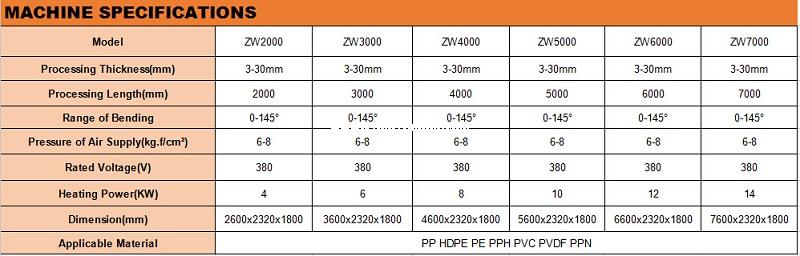

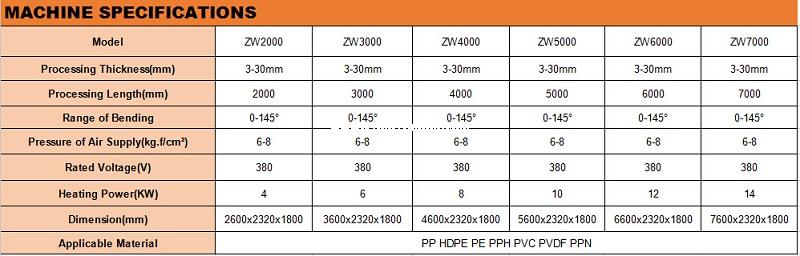

ZW3000 Plastic Sheet Bending Machine

ZW3000 Plastic Sheet Bending Machine

FEATURES

1. PLC touch-panel control system, capable of automatically adjusting the heating temperature, time and pressure according to the parameters of material under processing.

2. Brand-new integrated frame, highly reliable transmission mechanism, stable in work and superior in performance.

3. Sectional heating for models of 3 meter and larger, enabling large models to have the advantage of energy conservation, as same as the small models do, while processing two small workpieces.

4. Specialized anti-corrosive surface treatment technology, making the surface coating always new as time goes by.

5. Components imported from Japan for control system, with stable properties, lasting and endurable.

***Range of Application***

Manufacture of reservoirs, tanks and containers, manufacture of plastic apparatus, pipeline construction, ventilation systems, serial welding, water treatment systems, scrubbers, environmental technology, swimming pools, transport and logistics.

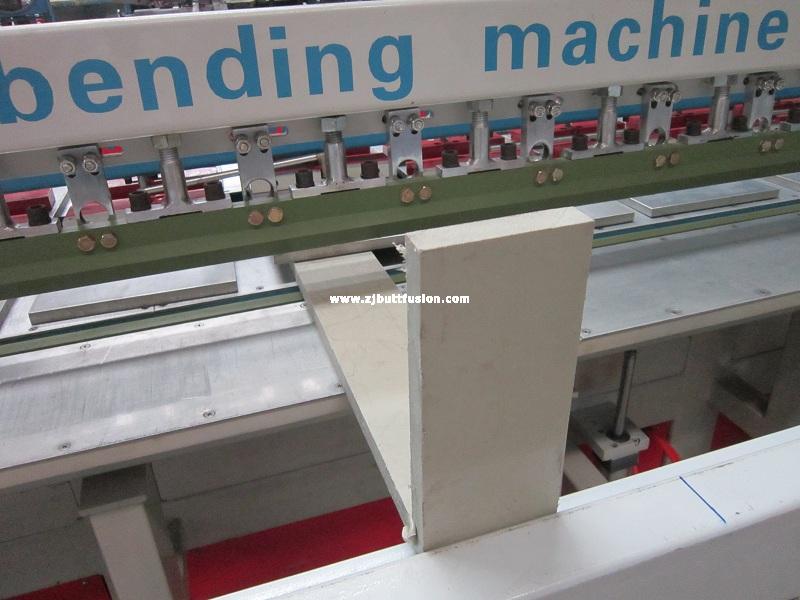

PICTURES

FEATURES

1. PLC touch-panel control system, capable of automatically adjusting the heating temperature, time and pressure according to the parameters of material under processing.

2. Brand-new integrated frame, highly reliable transmission mechanism, stable in work and superior in performance.

3. Sectional heating for models of 3 meter and larger, enabling large models to have the advantage of energy conservation, as same as the small models do, while processing two small workpieces.

4. Specialized anti-corrosive surface treatment technology, making the surface coating always new as time goes by.

5. Components imported from Japan for control system, with stable properties, lasting and endurable.

***Range of Application***

Manufacture of reservoirs, tanks and containers, manufacture of plastic apparatus, pipeline construction, ventilation systems, serial welding, water treatment systems, scrubbers, environmental technology, swimming pools, transport and logistics.

PICTURES